WHY WORK WITH US

Our consulting firm stands out

We provide expert advice to help your facilities achieve its full potential ensure safe, leak- free operations and business continuity

We offer tailored solutions that are underpinned by International standards including but not limited to ASME B 31.3, ASME Section VIII Division 1&2 and API 579 to support your unique business needs and drive remarkable outcomes

Our Company leadership formed by Angolan nationals with a vast experience in global and Angola oil and gas industry have a track record of proven results in the Engineering matters showcasing our ability to deliver tangible and impactful outcomes.

About Us

Driving experts in engineering consulting

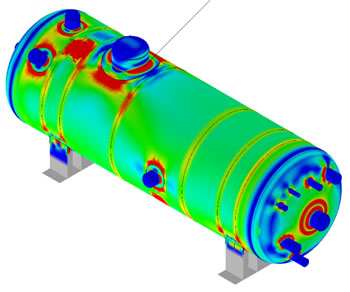

At Petromeches, we understand that pressure boundary integrity is the heart of the process and process safety of any oil and gas production and processing facility, our expertise in the area of fitness for service assessment for pipelines and pressure vessels do assist in informed business continuity decisions. In everything we do, our goal is to provide mechanical integrity solutions that help prevent loss of primary containment (LOPC) and ensure that fluid remains in the pipeline, thus saving the lives of people, FPSO and Production Platforms. We do this by combining five elements:

- Health and Safety are inherent to our Mechanical Integrity Solutions

- Use of subject matter knowledge and expertise (SME) - We thrive to technical excellence.

- Respect and value to our customers.

- Adherence to international standards, best practices, code of conduct and local government decrees.

- collaboration with international engineering institutions, including the institution of Mechanical Engineers in UK, UK Engineering Council & locally the Angola Engineering Council

Our services

We are experts in Mechanical integrity Assessments

Piping and pressure vessel fitness for service evaluations

We provide Mechanical Integrity assessments solutions through the following scopes:

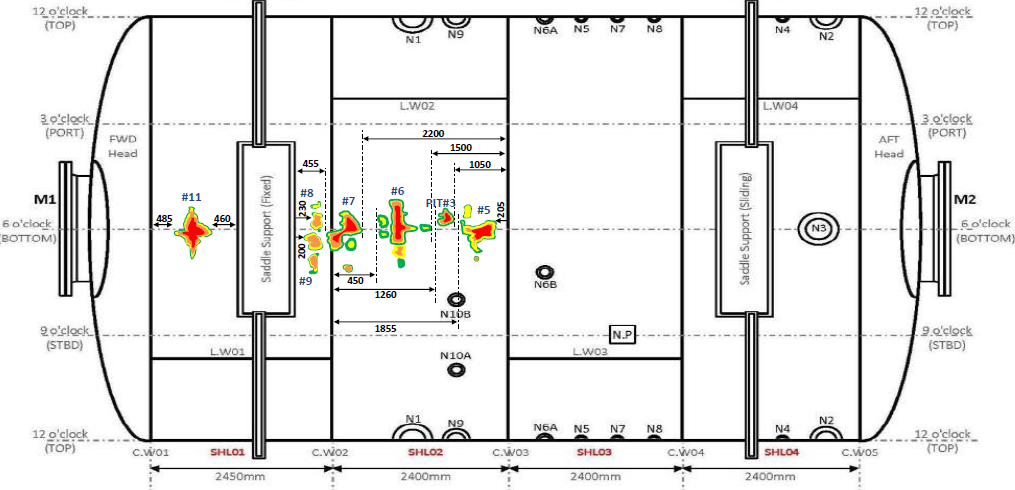

- Fitness for service assessments in accordance with ASME FFS-1/API579 and other relevant industry standards to inform about fitness for continued service of your asset piping and pressure vessels ,respectively:

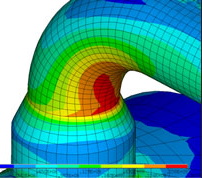

- ASME FFS-1/ API579 part 5, LTA Level 1,2 and 3 (Finite Element Analysis).

- API -579, Part 3 , piping components Brittle fracture.

- API 579 part 6-Pitting corrosion evaluation

- API 579 part 9 ,level 1,2&3- Crack like Flaws assessments.

- We will determine the remaining life of your asset damaged component (piping system) when deemed fit for continued services as well as provide sound technical and experience driven recommendations when it is deemed not fit for service.

- Fatigue life design and assessments of steel products per BS7608.

- Engineering Integrity anomaly repairs solutions-ASME PCC2

- Equipment maintenance strategy analysis.

Advanced Piping Vibration Analysis

It is estimated that 10% to 15% of offshore facilities pipe work failures are caused by vibration (Energy Institute). Changes in operation philosophies are inherent to any brownfield. These changes in operating philosophies when imposed by either plant aging, production profile changes, pipe supports, wall thickness, diameters, pessure, temperature flow direction, may cause the excitation source frequency to coincide with the system structural natural frequency.

- Mechanical Vibration Analysis

- Flow induced vibration(FIV) assessments

- Accoustic Induced Vibration(AIV) assessments

- Thermowells Vibration analysis.

- Corrosion Risk based analysis: API 580 and API 581 analysis We conduct RBA-Risk based assessments for evergreening your integrity programme.

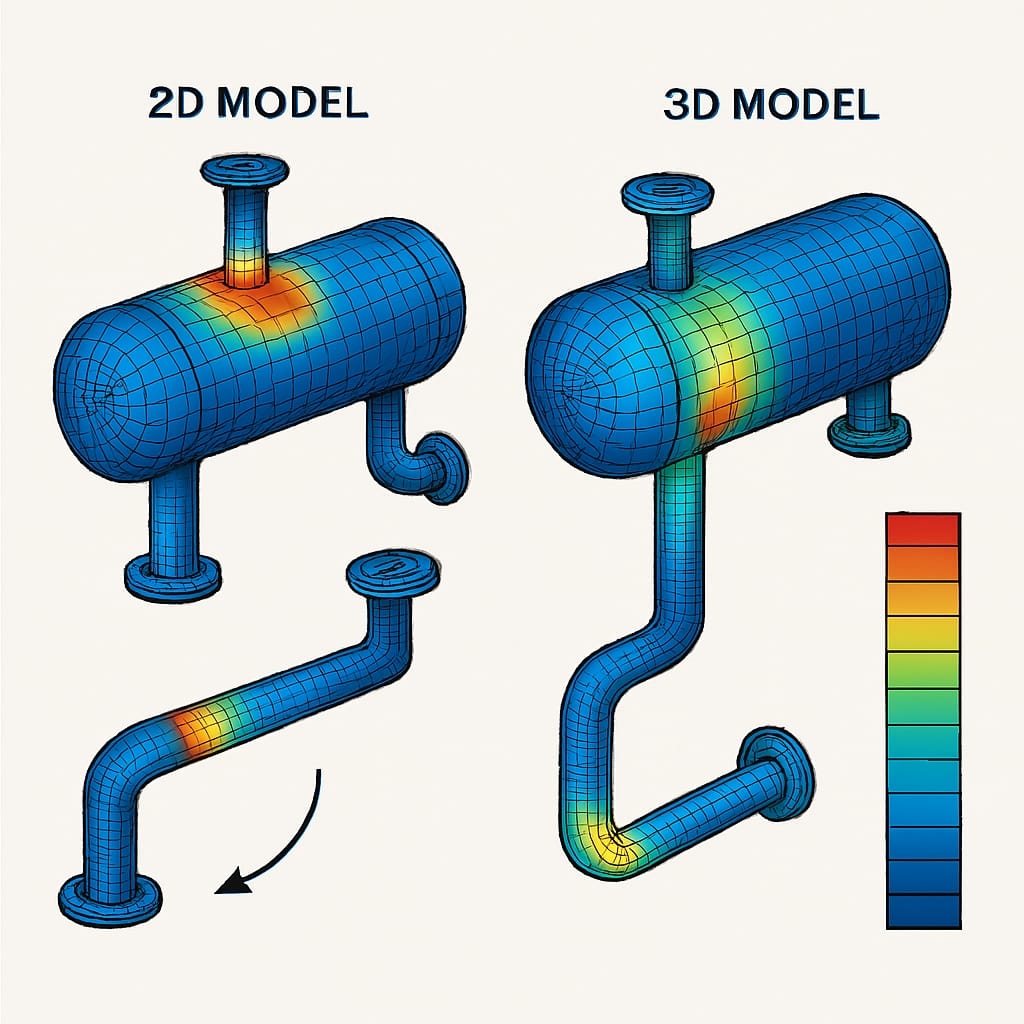

Piping Stress Analysis

Piping systems are subjected to several loading conditions during start ups, steady state operations and shut downs, however, in-sevice systems changes in the components geometries including pipe supports, wall thickness, diameters, pessure, temperature, flow direction and the presence of transient conditions, may lead to amplification of the stresses resulting in overstressing of the pipework leading to failures and loss of pimary containment.

We will conduct:

- Static stress analysis

- Dynamic advanced stress analysis.

- Nozzle loading assessments

- Spring hanger design and inservice performance analsys.

- We will provide sound technical driven recommendations that will ensure overstress-free system operations.

Valves

- We conduct Root Cause Failure Analysis of Valves.

- We carry out Valves Maintenance Strategy assessments.

- Valves Maintenance Strategy Optimization.

3D Modeling & Mechanical Design Services

At Petromeches, we offer cutting-edge solutions in mechanical design and virtual prototyping, leveraging advanced 3D modeling tools to bring your concepts to life with precision and efficiency:

- Parametric 3D Modeling: Expert design of parts, assemblies, and detailed 2D drawings

- Mechanical Project Development: Comprehensive design and simulation of mechanical systems and virtual prototypes

- Standardized Technical Drawings: Creation of drawings compliant with international standards (ISO, DIN, ASME)

- Simulation Services: Static and motion analysis to validate performance and optimize design integrity.

- Manufacturing Documentation: Generation of exploded views and Bills of Materials (BOM).

More services

Great diversity of services for their industry.

Pipe clamp connectors Engineering solutions.

- We conduct installed clamp integrity evaluations

- We Review clients installed clamp design in accordance with design codes and regulations.

- We provide Clamp Seal Ring specifications and selection based on customers applications.

Thread sealants

- We provide thread sealant Engineering solutions based on clients needs

- We provide thread sealant application procedure

- We recommend the best thread sealant products to suit your organisation needs.

Piping and pressure vessels Integrity anomalies repair solutions.

- We provide code based repair solutions that ensure pressure boundary Integrity

- We develop repair procedures and recommendations

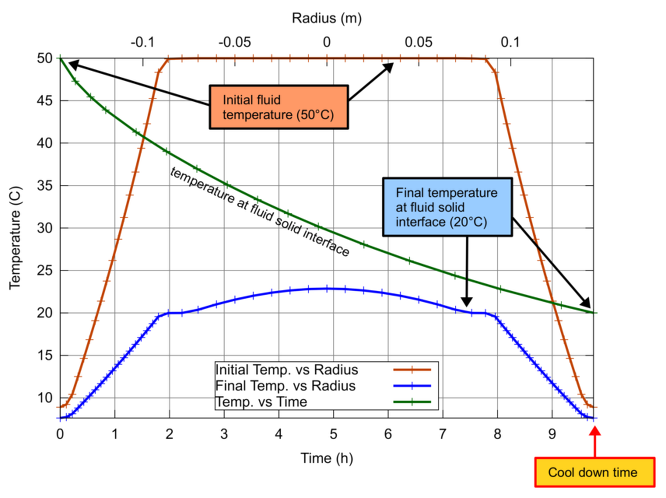

Through material fracture mechanics and thermodynamics principles we determine the time it takes for a pipe or metal to reach critical minimum metal temperatures thereby allowing the setting of correct process safety time such as alarms or trip set points to prevent embrittlement failures due to joule-thomson (J-T) effect.

Welding procedure qualifications reviews

- We review welding procedures in accordance with pocedure qualification records

- We conduct oversight of clients welding practices

Lifting on Certified and Uncertifid monorail beams

- We determine safe lift load assessments in accordance with AISC-American Institution of steel construction.

- We conduct oversight of clients lifting practices and procedures

Our leadership are members of Angola Engineering Council and IMechE and accredited through rigorous assessment processes.

GET IN TOUCH TODAY VIA WhatsApp

+244 922 143 500

CALL US 24/6

+244 922 143 500

MAKE A QUOTE

enquiries@petromeches.com

CMDT. Kwenha Street